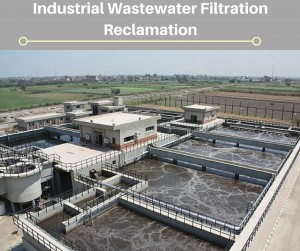

Industrial organizations utilize vast amounts of water to perform or support various engineering and manufacturing operations. These include cooling, processing, fabrication, manufacturing, and sanitation. Today, due to water scarcity from global warming, water reclamation and reuse is becoming an essential function for industrial factories. Hence, organizations are utilizing industrial wastewater filtration systems for water reclamation and reuse purposes.

Why is Water Reclamation Important?

The processes of water reclamation and reuse are designed to accomplish two functions:

- Wastewater can be treated to create another water resource, which can be used for general industrial tasks.

- By reusing wastewater, the amount of water effluents passed down to water bodies like lakes, beaches, and streams is reduced. It also results in a reduction of surface and ground water pollution.

Why is Industrial Wastewater Reclamation Required?

According to the US Geological Survey (USGS), in 2010, nearly 355 billion gallons per day (Bgal/d) were used throughout America. From this, 161 Bgal/d was withdrawn for thermoelectric power, 5.32 Bgal/d was withdrawn for mining, 115 Bgal/d for irrigation, and 15.9 Bgal/d self-supplied industrial withdrawals. The industrial sectors are the third largest users of water. Hence, industrial wastewater filtration systems are used to allow for safe and effective water treatment to provide water of adequate supply and quality.

What are the Various Technologies that can be Used for Water Recycling?

There are certain technologies that are applied for industrial water reclamation today. Four popular examples are given below.

- Carbon Adsorption: As the name suggests, the carbon is placed in a filter, and is used to adsorb contaminants present in water. Contaminants can include radon, chlorine, fluorine, and bad odors and tastes.

- Advanced Oxidation: This refers to chemical treatment procedures, which help eliminate organic and inorganic materials in wastewater. Oxidation is created using chemical processes involving UV light, or hydrogen peroxide.

- Reverse Osmosis (RO): This water purification technology involves using semi-absorbent membranes. The membranes are used to eliminate hazardous molecules and ions from water. The water is pushed through the membrane at high pressures to remove the particles.

- Ultraviolet Disinfection: Also known as Ultraviolet Germicidal Irradiation (UVGI), this technology utilizes ultraviolet light to destroy microorganisms in water. The UV light eliminates large biomolecules, which results in the microorganisms being unable to function.

The use of these technologies help reduce water wastage in industrial facilities. They also ensure that all industrial processes are performed and completed properly, while reducing the dependence on fresh water. All these reasons justify the need for water reclamation processes, and the use of industrial wastewater filtration systems.