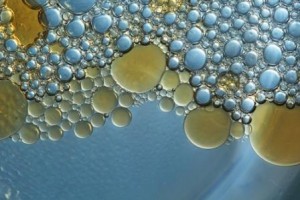

Water and oil are two substances that don’t mix with each other, but they often found together in nature. This water-oil emulsion makes the resulting compound unusable. This emulsion causes a major problem in crude oil refining plants and various other industries. These emulsions may hamper equipment or processes, causing expensive breakdowns, and downtime. A variety of electrolytic, physical, and chemical methods are adopted for separating these emulsions. Chemical emulsion breakers are economical and effective than other methods. This post will help a novice understand emulsion breakers, and their importance in the process industries.

Understanding Emulsion Breakers

Emulsion breakers, also known as demulsifiers, are a group of specialty chemicals used to separate emulsions of water-in-oil and oil-in-water (reverse emulsions). These chemicals are used for effective oil recovery, and to improve the quality of reusable water. These emulsion breakers also help protect downstream facilities.

Types of Emulsion Breakers

There are various types of emulsion breakers available in the market. This abundant variety is due to two reasons: companies manufacturing and labeling their own brands, and high demand for specific emulsion breakers. However, the most common types of chemical emulsifiers include the following:

- Epoxy resins

- Acid or base catalyzed phenol-formaldehyde resins

- Polyethylenimines

- Polyamines

- Dendrimer

- Di-epoxides

- Polyols

The commercial demulsifier formulas are usually a mixture of two, or three types of different chemicals in carrier solvents. Some of these solvents used for creating these breakers are heavy aromatic naphtha, xylene, diesel, isopropanol, 2-ethylhexanol, and methanol.

How Demulsification can be a Challenge to Process Industries?

Demulsification is an advantage as well as a challenge to process industries. The selection of a poor demulsifier can affect an application in the following ways.

- Corrosion damage to storage tanks and pipelines

- Substance foaming

- Increase in emulsion viscosity

- Increase in power and energy consumption

5 Reasons Why Process Industries Should Use Emulsion Breakers

Process industries should use chemical emulsion breakers because they contribute in the following ways:

- High operational efficiency

- Low maintenance costs

- Eco-friendly operation through effective oil recycling

- They reduce wear on pumps while increasing production rates

- They improve vessel efficiency

Finding a right emulsion breaker for your industrial process is very essential. You can always check with your manufacturer or supplier if a particular demulsifier will work for light, or heavy crude oils. Also, if they are suited for different environmental conditions – such as winter and summer. HPI Processes, Inc. is a manufacturer of environmental friendly technology products for process industries. It provides industrial-grade emulsion breakers for the crude oil industry.